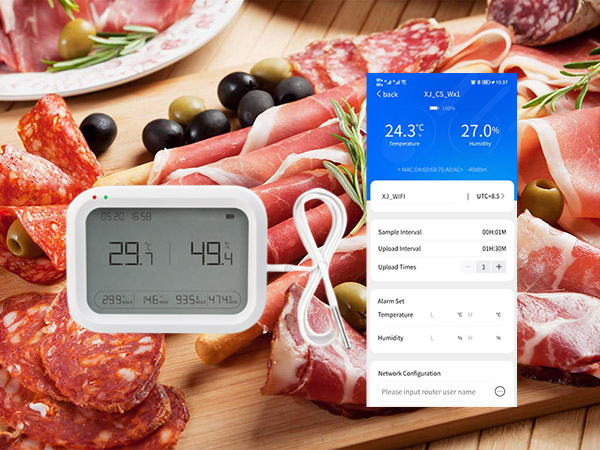

Freshliance COEUS-WIFI offers temperature sensors that allow monitoring and recording of temperature both in rooms where meat is processed and the temperature of the meat itself to help you comply with HACCP.

Meat products are an indispensable food in our daily life, accounting for a large proportion of our daily diet, and their safety is directly related to people’s health and social stability. For meat products, temperature control during production and processing is particularly important. Meat plants, including all enterprises involved in the production of meat or the production of cured meat products (sausages, hams, pies and other animal products), are required to meet relevant standards and regulations regarding the conditions in which meat products are produced, processed and stored.

Pursuant to the Act of October 30, 2003 amending the Act on health conditions of food and nutrition and its amendments, each production plant is required to implement and apply the principles of the HACCP system. The system consists in conducting a hazard analysis and indicating which points of the food production process are critical —there may be hazards affecting the health quality of the final product. For meat production and processing, critical points are all places where the meat temperature can rise, which can lead to a rapid increase in the number of microorganisms and, consequently, damage to the meat. Most often this is associated with too high storage temperatures or breaks in the cold supply chain. The following are suggested temperature for meat processing plant:

| Stage | Temperature control object | Temperature control requirements |

Production of edible animal casings | Room temperature | ≤25℃ |

To be processed | Cold fresh meat temporary storage room temperature | 0℃~4℃ |

Marinated | Marinating room temperature | 2℃~4℃ |

Sterilization | Product core temperature | ≥ 70°C |

Modified atmosphere packaging marinated meat products cooling | Cooling room temperature | ≤ 10℃ |

Modified atmosphere packaging marinated meat products packaging | Packing room temperature | ≤ 12°C |

Chilled meat packaging | Packing room temperature | ≤ 12°C |

Thermal storage | Product core temperature | ≥60 ℃ |

Refrigerated storage | Storage room temperature | 0 ℃~7℃ |

Refrigerated storage of edible animal casings | Storage room temperature | 0 ℃~10℃ |

Frozen storage | Product core temperature | ≤ -18℃ |

Freezer storage | Daily temperature fluctuations | ≤ 1°C |

Summer /Extended expiration date | Cooked bacon storage room temperature | 0℃~10℃ |

These points are designated as critical control points and should be subject to ongoing surveillance. Temperature recorders should be placed in these workplaces, and once temperature exceeds these values, which will cause the alarm to be triggered.

The solution designed to monitor environmental conditions in large facilities is Freshliance Cloud – a server platform collecting and processing data from COEUS-WIFI wireless temperature sensor. The platform is designed for objects in which a dozen measuring points are monitored. Data to the platform can be sent from any location, and the user can access it via a web browser.The system consists of wireless loggers, gateways, i.e. concentrators, which receive measurements wirelessly from sensors and send them over the Internet to the cloud platform – Freshliance Cloud. The server platform is the “brain” of the entire system, it is there that decisions are made to send SMS / e-mail notifications, where measurement data is collected, which the user can access from anywhere. Measurement data can come from temperature monitor located in different places, you can freely manage them, group them according to your needs or grant access to individual temperature recorders to selected users. The platform is maintained by Freshliance, so the user does not have to worry about maintenance, maintenance or software update. COEUS-WIFI offers temperature sensors that allow monitoring and recording of temperature both in rooms where meat is processed and the temperature of the meat itself, thanks to a special probe, which is designed for contact with food. The loggers have a wide range of work, so they can work both in rooms where meat is processed and in cold stores. The temperature loggers can work autonomously (saving measurements in the built-in memory) and in cooperation with Freshliance Cloud, enabling constant temperature supervision and notifications.

English

English Español

Español Русский

Русский Français

Français Deutsch

Deutsch عربي

عربي 中文

中文